Work steps:

1. Screw the pH meter into the pH meter interface, connect the pipes of the dosing device, and then check each interface and tighten it to prevent fluid leakage.

2. Connect the power supply of the metering pump: Open the junction box of the electric control cabinet and connect the fourth-wire power cord that meets the requirements of the metering pump motor to the corresponding terminal block.

3. Close the drain valve.

4. According to the prescribed liquid concentration, according to the tank capacity and concentration of the medicine, measure the amount of medicine and water, add the medicine to the medicine tank, open the water supply valve, and add the required amount of water.

5. Specify solution: Inject a certain amount of medicine (solid or liquid) into the solution tank, open the water supply valve to inject water, stop injecting water when the liquid level reaches the specified wave surface, adjust the metering device to the set dosage, and then open the The solution tank first causes the valve to start dosing.

6. Dosing medicine: Open the valve of the dosing system, adjust the dosage of the metering pump to a certain value, start the metering pump, add medicine to the dosing point, and constantly adjust the dosage of the metering pump to ensure that the dosage meets the requirements. If the process requirements cannot be met, the concentration of the prepared medicinal solution needs to be readjusted. The automatic dosing device is equipped with a metering pump. The metering pump is a positive displacement type with adjustable stroke.

7. The residue in the solution tank can be discharged through the sewage pipe, and the liquid level in the solution tank can be measured according to the liquid level gauge.

8. When the medicine in the dosing box drops below the relatively low level, the dosing pump automatically stops working.

9. When the pH value of the medicinal solution in the medicinal plant is greater than or less than a certain value (the value can be set by referring to the attached pH meter instructions), the dosing pump will automatically stop working.

10. When the conductivity is greater than the set value (the value can be set by referring to the attached electric signal rate instruction manual), the drain valve opens to drain the sewage until the conductivity is lower than the set value, and then automatically stops.

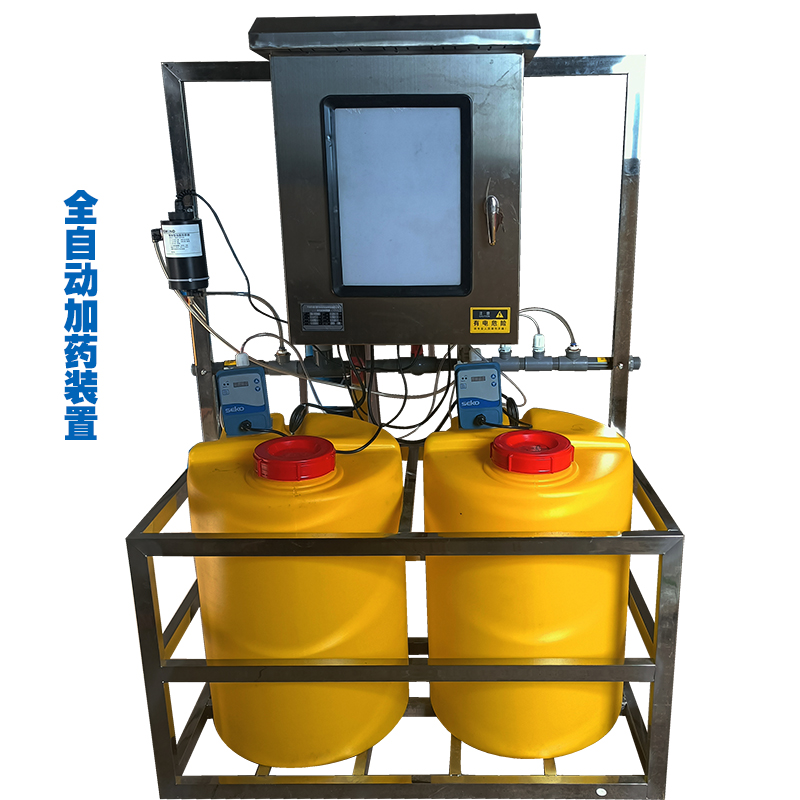

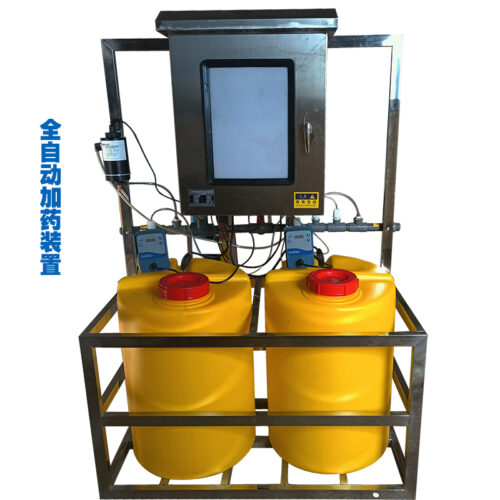

Dosing Device

Structural description of dosing device:

1. The dosing device mainly consists of solution tank, stirrer (optional), metering pump, control cabinet, pipeline, pressure gauge, liquid level gauge, liquid level sensor (optional), conductivity (optional), PH meter (optional), corrosion online monitor (optional) bracket, etc.

2. All components of the dosing device are centrally installed on a frame, and are compactly and reasonably combined into an independent dosing unit, which greatly reduces the workload of chemical design and on-site installation and reduces the floor space.

3. The solution tank is equipped with a plate liquid level gauge, which can realize local display and has a low liquid level pump shutdown protection function.

4. Manual dosing and automatic dosing can be realized on-site. All electrical appliances and instruments are centrally assembled in the electrical cabinet. The structure is simple, making commissioning and operation safe and convenient.